Microsensor Electromagnetic Flow Meter Overview

The Microsensor electromagnetic flow meter is designed for accurate measurement of fluid flow in various industrial and commercial applications. By utilizing electromagnetic technology, this flow meter provides precise readings, making it suitable for fluids with different levels of conductivity. It offers stable, reliable flow monitoring for use in sectors such as water treatment, food processing, and chemical industries.

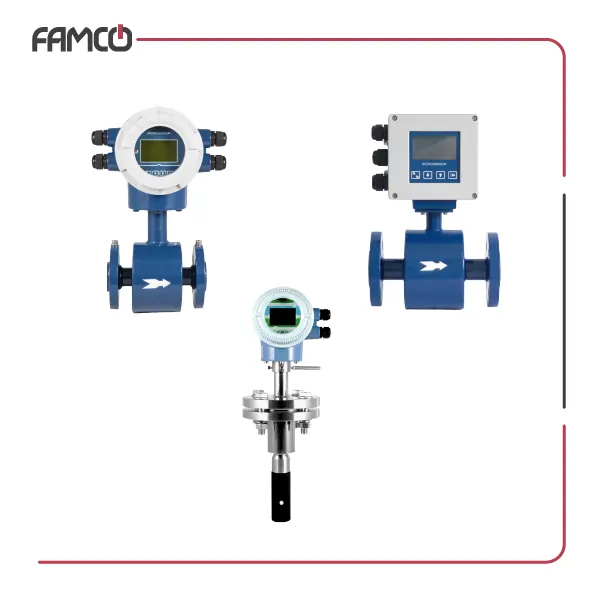

Microsensor Electromagnetic Flow Meter Models

Microsensor offers a range of electromagnetic flow meter models that vary by size, pressure capacity, and additional features to meet diverse application needs.

Models are available for different pipe diameters and flow ranges, allowing users to choose the best fit based on the specific volume and type of fluid they wish to measure. Certain models also include digital displays and connectivity options, enhancing user convenience and data accessibility.

Microsensor Electromagnetic Flow Meter Applications

The Microsensor electromagnetic flow meter is suitable for applications across multiple industries, including water and wastewater management, chemical processing, and food and beverage manufacturing. It excels in environments requiring precise and non-intrusive flow measurement for conductive liquids, making it ideal for monitoring flow in pipelines, treatment plants, and manufacturing facilities where fluid accuracy is critical.

Microsensor Electromagnetic Flow Meter Advantages

This flow meter offers several notable advantages, including high accuracy and quick response times, making it reliable for demanding applications. The non-mechanical design reduces the risk of wear and tear, leading to a longer-lasting measurement tool. Additionally, its compatibility with a variety of conductive liquids provides flexibility across different industries, and the flow meter is designed to minimize pressure loss, supporting consistent fluid movement.

Microsensor Electromagnetic Flow Meter Maintenance

Routine maintenance for the Microsensor electromagnetic flow meter includes regular inspections to check for buildup or residue on electrodes and to confirm that connections remain secure. Cleaning the sensors periodically prevents contamination, supporting accurate flow readings. A professional checkup, especially in harsh industrial environments, further contributes to the meter’s reliable performance over time.

Microsensor Electromagnetic Flow Meter Installation

Installation of the Microsensor electromagnetic flow meter is straightforward, with placement directly into the pipeline. Professional installation is recommended to properly align the meter with the flow direction and secure all connections. For best results, the flow meter should be installed in a location with stable fluid flow, avoiding high turbulence areas. Proper setup ensures accurate and consistent readings, as well as smooth integration with the existing flow system.

Microsensor Electromagnetic Flow Meter Price

The price of a Microsensor electromagnetic flow meter varies depending on the model, size, and additional features. Basic models designed for smaller applications offer a cost-effective solution, while advanced models with added capabilities, such as digital displays or data logging, may be priced higher. Microsensor provides a range of options to accommodate different budgets, allowing for precise flow measurement at competitive pricing for both small and large-scale needs.