For precise measurement, management, and monitoring of time and count-related operations, Autonics Counter and Timer devices are crucial in a variety of sectors. These devices have a wide variety of applications and are commonly utilized in automation systems. This article will cover the many varieties, attributes, advantages, and possible issues with Autonics Counter and Timer devices in addition to their main uses and costs.

All types of Autonics Counter And Timer

A range of counters and timers are available from Autonics to meet various industrial and commercial requirements. The main categories are broken out as follows:

Digital Counters

Due to their precision and effectiveness in counting procedures, digital counters are the most often utilized in industries. Usually used in manufacturing, packing, and assembly lines, these counters are capable of counting a wide range of events, pulses, or objects. They provide precise counting and may be easily programmed for particular uses.

Digital Timers

The exact timing functions required in industrial operations are provided by Autonics digital timers. In order to guarantee that activities are finished within the allotted time, these timers are used to regulate durations and intervals. Their versatility in accommodating different timing requirements stems from their ability to be set for a range of periods, including seconds, minutes, and hours.

Counter Timer Combinations

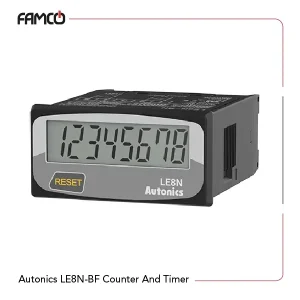

Combination devices by Autonics combine the capabilities of a timer and a counter into one gadget. With this dual feature, users may measure time and count at the same time. This is especially helpful in applications like batch processing and conveyor belt systems where both activities must occur concurrently.

Features of Autonics Counter And Timer

The extensive feature set of Autonics Counter and Timer devices is well-known. The following are some salient characteristics that set these devices apart:

Counting functions

These devices provide dependable and adaptable counting functions, including differential, up, and down counting. Autonics counters are appropriate for sectors demanding quick and precise measurements since they can manage high-speed counting.

Timing functions

Industrial operations are timed precisely thanks to the high precision changeable timing settings provided by Autonics timers. These devices provide a variety of timing tasks, from interval timing to delayed start, to meet various automation demands.

Input types

Numerous input formats, including touch and non-contact inputs like sensors, are supported by Autonics Counter and Timer devices. Because of this versatility, users may choose the best input method for their particular application, which improves system performance as a whole.

Benefits of Autonics Counter And Timer

There are many significant advantages to using Autonics Counter and Timer devices in automation systems.

Versatility

These automatic counters’ adaptability is one of its main features. Because they can perform a variety of counting and timing operations, they may be employed in a broad range of sectors, from manufacturing to packing. These devices provide an adaptable solution for a variety of applications, such as monitoring the items on a conveyor belt or controlling the time of a heating operation.

Reliability

Because Autonics products are long-lasting, they work dependably even under harsh conditions. They guarantee less downtime and reliable outcomes since they are designed to resist the demands of industrial operation.

Accuracy

For counting and timing applications, accuracy and precision are essential, and Autonics provides both. These instruments reduce mistakes by very precise readings, which improves operational efficiency and lowers costs.

Problems of Autonics Counter And Timer

Despite the great dependability of Autonics Counter and Timer devices, customers may sometimes run across the following problems:

Counting errors

Sometimes bad wiring or inaccurate calibration might lead to counting inaccuracies. To prevent such issues, proper setup and autonics counter wiring are essential.

Timing inaccuracies

When the timer is not set properly or when external elements like temperature changes interfere with the device’s functioning, timing errors may occur. Preventing such mistakes may be aided by routine maintenance and calibration.

Display failures

An Autonics counter or timer’s display may sometimes malfunction, just like any other electrical gadget, resulting in inaccurate readings or data loss. Usually, this may be fixed by calling customer service or by following the instructions in the autonics counter and timer manual.

Applications of Autonics Counter And Timer

Autonics timers and counters are essential to many different businesses. The following are some important applications:

Manufacturing

Counters and timers are critical components in industrial settings because they help maintain track of production volumes and guarantee that equipment runs within predetermined time limits. They save waste and increase efficiency.

Packaging

For duties like counting items before they are wrapped or managing the timing of packaging operations, the packaging sector significantly depends on counters and timers.

Automotive

These devices are used in quality control and assembly lines within the automobile sector. Timer devices control manufacturing speed, while counters make that the right amount of components are built.

Textile Industry

Counters and timers are very useful in the textile sector, especially in operations like fabric manufacture and dyeing. These tools aid in preserving uniformity and guarantee accurate control throughout different manufacturing phases.

Autonics Counter And Timer Price

Depending on the features and model, Autonics Counter and Timer devices have different prices. More complex versions with more features may cost more, while basic ones, like the Autonics counter timer CT6S-1P4, are usually more inexpensive. Autonics ensures that businesses of all sizes may take advantage of their technology by providing a variety of devices to suit their financial demands.

With a blend of dependability, precision, and adaptability, Autonics Counter and Timer devices provide a number of options for many sectors. When configured correctly, these devices are typically resilient and dependable, while there may be rare problems like counting mistakes or display failures. Autonics timers and counters provide vital features to guarantee seamless, productive operations, whether you work in the manufacturing, packaging, or even textile sectors.

Which autonics counter And Timer is best for your requirements may be chosen with knowledge based on features, advantages, and possible drawbacks.