What is Counter and Timer?

Counters and timers are essential electronic devices used in various industrial, commercial, and consumer applications to measure, count, or control the passage of time and the occurrence of events.

Counters are devices that count discrete events or occurrences, typically triggered by external inputs like pulses or signals. They are widely used in automation, production lines, and machinery to track events such as product quantities, machine cycles, or customer entries.

Timers are devices used to measure time intervals or delay operations. They can be set to perform specific tasks at predefined times or to start and stop processes after a certain duration.

Timers are essential for process control, ensuring that operations occur for a precise duration. Together, counters and timers are crucial in managing and optimizing industrial processes, ensuring efficient operation, timing, and accurate counting of events.

Counter and Timer Types

There are various types of counters and timers, each designed for different applications:

Counter Types:

Up Counters: Up counters count events in an ascending order, incrementing by one each time a signal is received. They are commonly used in manufacturing to count products, parts, or pulses generated by sensors.

Down Counters: Down counters work in reverse, counting down from a preset value. They are often used in systems where the operator needs to know how many items are left to complete a batch or process.

Bidirectional Counters: Bidirectional counters can count both up and down, depending on the direction of input pulses. These are useful in applications where the number of events can increase or decrease, such as in positioning systems or conveyor belts that reverse direction.

Preset Counters: These counters can be set to a specific value and will stop or trigger an action once that value is reached. They are often used in automated systems where a task must be completed after counting a certain number of operations or parts.

Digital Counters: Digital counters display counted values on an electronic display. They are programmable, offering more flexibility in counting operations and interfacing with other digital devices like PLCs (Programmable Logic Controllers).

Mechanical Counters: These are traditional counters that operate through mechanical movements, such as rotary or linear counting mechanisms. They are more durable but less flexible compared to digital counters and are typically used in environments without access to electrical power.

Timer Types:

Delay On Timers: These timers initiate a delay after an input signal is received and then start a process or trigger an action once the set time has elapsed. Delay on timers are commonly used in HVAC systems and industrial processes where a controlled delay is necessary before starting equipment.

Delay Off Timers: In contrast to delay on timers, these timers delay the stopping of an operation after a signal is received. Delay off timers are used in lighting systems, conveyor systems, and motor control applications where the equipment needs to stay operational for a set duration after being switched off.

Interval Timers: Interval timers start timing as soon as they receive a signal and stop after a set time, regardless of the state of the input. They are used in heating, cooling, or any process that needs to run for a defined time period.

Cyclic Timers: Cyclic timers repeatedly turn a process on and off at preset intervals. These timers are used in applications such as irrigation systems, periodic lighting control, and automated machinery where repetitive actions are necessary.

Multifunction Timers: Multifunction timers offer flexibility by incorporating several timing modes into a single device, allowing users to choose the desired function based on their application needs. They are used in complex automation systems where different timing functionalities may be required at various stages of a process.

Analog Timers: Analog timers typically use mechanical or electronic systems to measure time intervals and are often adjusted manually. They are simple, cost-effective solutions for basic time management in various industrial or commercial settings.

Counter and Timer Advantages

Counters and timers provide numerous benefits across different applications. Key advantages include:

Precision and Accuracy: Timers and counters allow for precise control and measurement of events or time intervals, which is crucial for optimizing industrial processes, ensuring quality control, and improving production efficiency.

Automation: These devices enhance automation by controlling processes that need to start, stop, or repeat after a specific number of events or during certain time intervals. This reduces manual intervention and increases consistency in operations. Increased

Efficiency: By using counters and timers, industries can manage resources more effectively, ensuring processes run at optimal times and stop at the correct moment. This minimizes energy consumption and reduces waste.

Customization: Many counters and timers can be programmed or adjusted for specific tasks, allowing them to cater to different needs. Whether it’s setting the number of products to count or controlling the duration of machine operation, these devices offer a high degree of flexibility.

Cost-Effective: Counters and timers are relatively inexpensive components that provide significant operational benefits. Their ability to improve process control, reduce downtime, and increase automation makes them a cost-effective solution for many industries.

Durability and Reliability: Most industrial counters and timers are designed to withstand harsh conditions such as extreme temperatures, moisture, dust, and vibrations, making them reliable in demanding environments like manufacturing plants or construction sites.

Counter and Timer Fields of Use

Counters and timers are used across various industries for different purposes. Some common fields of use include:

Manufacturing: Counters are essential for tracking the production quantity of items on an assembly line, controlling machine cycles, and counting the number of operations completed. Timers are used to regulate machine run times, delay processes, and synchronize equipment for optimal performance.

Automation and Robotics: In automation systems, counters monitor repetitive tasks, while timers control process duration, equipment start/stop times, and task sequencing. These devices ensure the smooth functioning of automated machines and robotic systems.

HVAC Systems: Timers control the operation of heating, ventilation, and air conditioning systems to ensure they run only when necessary, reducing energy consumption. They are also used to delay the start or stop of fans, pumps, and other HVAC components.

Food and Beverage Industry: Counters help track the number of items processed on production lines, while timers are used to control cooking, cooling, and packaging durations. Timers ensure that food products are processed consistently, meeting quality standards.

Retail and Consumer Electronics: Digital counters are widely used in retail to count customer entries, track inventory, and monitor sales transactions. Timers are used in consumer electronics for functions like automatic shutdown, sleep mode, or timed power on/off.

Irrigation Systems: Cyclic timers control the duration and frequency of irrigation, ensuring plants and crops receive the appropriate amount of water at regular intervals, improving water management efficiency.

Traffic Control Systems: Timers are integral in traffic lights and pedestrian crossing systems to manage the flow of traffic and ensure safe, timed transitions between signals.

Construction and Heavy Machinery: Counters are used in construction equipment to monitor machine cycles, while timers manage the operation duration of heavy machinery. This helps in maintenance scheduling and efficient use of resources.

Counter and Timer Brands

Several manufacturers specialize in the production of reliable counters and timers for industrial use. Some of the leading brands include:

Omron: Omron is a global leader in automation solutions, providing a wide range of counters and timers for industrial applications. Their products are known for high performance, durability, and precision.

Schneider Electric: Schneider Electric offers a variety of timers and counters designed for industrial automation and process control. Their solutions are widely used in manufacturing, HVAC systems, and energy management.

Siemens: Siemens is a major player in industrial automation, offering high-quality digital counters and programmable timers. Their products are recognized for their robustness and adaptability to complex industrial environments.

Honeywell: Honeywell produces a wide range of industrial timers and counters that are known for reliability and accuracy. They are widely used in sectors such as manufacturing, transportation, and energy.

Panasonic: Panasonic provides digital timers and counters that are used in various industrial and consumer applications. Their devices are known for ease of use, flexibility, and energy efficiency.

Red Lion Controls: Red Lion Controls specializes in industrial automation and control devices, offering high-precision digital counters and multifunction timers. Their products are ideal for harsh industrial environments.

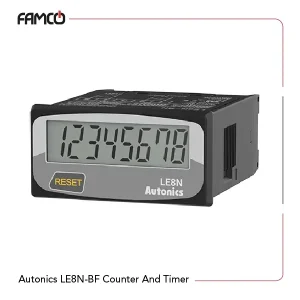

Autonics: Autonics is a leading manufacturer of industrial automation devices, including counters and timers. Their products are recognized for being user-friendly and cost-effective, with a wide variety of models suited for different applications.

Counter and Timer Price

The cost of counters and timers varies widely depending on the type, features, and brand. You can contact out experts at Famco to help you choose the suitable and cost effective product the best matches your needs.