How Does a Water Pump Work?

As we explore the world of these pumps, digging into their types, applications, and the intelligent science behind water pump work and function, we discover their role in our daily lives. Read this article as we unravel the details of fluid dynamics.

What Is a Water Pump?

Water pumps are inseparable parts of moving liquids, tirelessly working to shift water from one place to another. These hardworking machines are essential to various settings, from construction sites to homes, ensuring smooth water flow.

A water pump moves water between two points, effectively managing excess water where needed. Construction sites use these pumps to control water levels, while homes benefit from booster pumps that increase water pressure. So, water pumps meet the specific needs of different industries, homes, and even ships.

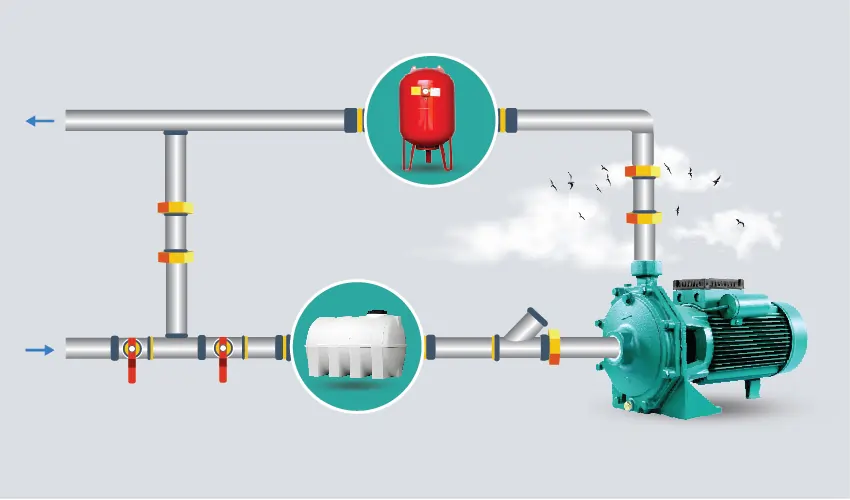

The water pump function is characterized by its efficiency, enabling rapid pressure changes within a system to facilitate the intake and expulsion of water. Different pump types employ various movements, such as the back-and-forth motion of a diaphragm or the turning motion to seal pump components and adjust pressure. The core of this efficiency lies in establishing a low-pressure environment inside the pump, similar to sipping through a straw.

Water pumps use methods like rotating an impeller to generate a low-pressure space promptly filled with water. It ensures a continuous flow for the situation’s specific needs, whether a boat expelling water or a booster pump increasing water pressure at home.

Water Pump Types and Applications

We have discussed the fundamentals of water pump work and its role in fluid transport. Now, let’s explore the landscape of water pump types and their applications.

Centrifugal Water Pump

Centrifugal pumps take the spotlight with their rotating impeller, efficiently moving water and boosting discharge flow. They come in various forms, including trash, submersible, and standard models. These pumps handle fluids with low viscosity and excel in applications where high flow rates are crucial. Their versatility allows them to find a place in tasks ranging from dewatering construction sites to facilitating water transfer in residential settings.

Positive Displacement Water Pump

Positive displacement pumps operate differently. They provide a constant flow rate through mechanical contraction and diaphragm stretch. These pumps are indispensable for handling high-viscosity fluids and solids, finding widespread use across various industries. They excel in applications that demand a balance of high pressure and low flow, displaying their reliability in various industrial processes.

Types of Water Pump Work Based on Applications

The water pump function significantly boosts agricultural productivity, meets residential water pressure needs, addresses specific challenges with specialty pumps, and embraces sustainable solutions with solar pumps. Each type of water pump plays a crucial role in ensuring the efficient flow of water where it matters most.

Agricultural Pumps

Agricultural pumps are crucial in rural areas and are indispensable for robust crop production. These devices cater to diverse water removal needs in agricultural settings, from submersible to centrifugal monoblock pumps. With their versatility, submersible utility pumps emerge as ideal for numerous water-related agricultural applications.

Residential Pumps

Residential pumps come in various flow rates and power capacities and meet specific water pressure requirements for homes. Options include self-priming regenerative, submersible, centrifugal, borewell compressor, and shallow well pumps. Among these water pump work and types, the ubiquitous booster pump stands out as a typical residential companion, which works diligently to elevate household water pressure.

Specialty Pumps

These pumps are for specific purposes, catering to unique applications. Each serves a distinct function, from sprinkler and pond or fountain pumps to power take-off (PTO) pumps and electric chemical pumps. Specialty pumps prove their worth in scenarios ranging from maintaining pool covers to handling chemical processes.

Solar Pumps

Solar water pumps are heroes of efficiency. Despite their higher installation cost, their independence from conventional electricity sources makes them cost-effective. By harnessing solar energy, these pumps operate seamlessly, providing an eco-friendly alternative for water pumping needs.

How Does a Water Pump Work?

Have you ever wondered how a water pump does its magic? After exploring their types and applications, let’s simplify the mechanics behind water pumps. Understanding the water pump work helps clarify their diverse applications, ranging from simple manual pumps in remote areas to sophisticated jet and centrifugal pumps that power our everyday water systems.

Manual Pumps

Imagine a pump in a small village. In the case of a manual pump, you become the engine. Pushing a handle up and down creates a vacuum that draws water from the well. As you lift the handle, the pressure you generate closes a valve, preventing water from returning to the well while simultaneously opening another valve to allow water to be expelled. This straightforward, hands-on method is ideal for places without electricity.

Jet Pumps

Jet pumps are often above wells and function like extended straws. They draw water from the well and propel it into a distribution tank, creating a vacuum that pulls water upward with the assistance of atmospheric pressure. Most jet pumps use electricity to power their water pump function. However, when electricity is unavailable, some jet pumps rely on gasoline or diesel engines to carry out their water pump work.

Centrifugal Pumps

Centrifugal pumps use a rotating impeller to harness centrifugal force for fluid movement. As the fluid enters and exits through the impeller’s tips, its velocity and pressure increase, directing it toward the pump’s outlet. These pumps are efficient movers in various water systems.

Water Pressure Pumps

Water pressure pumps, the workhorses of fluid movement, rely on positive displacement and kinetic energy. Whether powered by AC, DC, gasoline, or diesel, they drive the motor to generate the pressure necessary to propel water through pipes. These pumps are the backbone of well water systems, efficiently lifting water and ensuring delivery to the required locations.

Water Pump Components

While a water pump might seem straightforward, its efficiency stems from various intricate components seamlessly working together to perform the water pump function. Let’s explore the main components that collaborate to create this practical equipment.

Hub or Pulley

The pulley is the heart of the water pump’s motion, transferring movement from the drive belt to the bearing spindle and playing a crucial role in mediating torque. It’s constructed from robust steel, cast iron, or sheet metal materials. It ensures durability under the intense pressure and force exerted by the drive belt.

Spindle Bearing

After the pulley, the spindle bearing assumes center stage, receiving the turning force from the pulley and transferring it to the next component in line—the impeller. The design and quality of the bearing are pivotal factors determining the water pump’s lifespan. It has two types, roller-ball and ball-ball. The roller-ball design prevails for its durability and smooth function, contributing to the overall reliability of the water pump.

Body

The body of the water pump is like its primary structure. It holds the liquid and helps move its parts around. This part is made from solid materials like lightweight aluminum or cast iron, and it can handle the pressure from the water inside. One end connects to the pulley, and on the other, it joins with the car’s cooling system. It forms the basic setup that makes the water pump work.

Seal

The seal is essential for safeguarding the bearing from corrosion. As the bearing comprises metal balls, exposure to liquid presents a risk of corrosion. This component is a protective barrier, preventing contamination and ensuring a tight seal. Modern dynamic seals contribute to the longevity of water pumps when employed with high-quality liquid.

Impeller

The impeller elevates pressure and liquid flow by catching the liquid in its fins and amplifying its rotation-driven flow through the torque derived from the pulley and bearings. This piece is made from plastic, metal, or cast iron, and plays a vital role in the water pump function. Its specifications, like diameter and fin count, determine how much pressure the pump can create.

Conclusion

This article discussed water pump work and its components—the hub, spindle bearing, body, seal, and impeller. From the rhythmic motion of a manual pump to the whirring efficiency of centrifugal pumps, we discuss the mysteries behind these mechanisms, revealing how they power industries and homes. If you have questions about choosing the best option for your setting, leave a message in the comments section below.

FAQ

What are the different types of water pumps?

Various types of water pumps, including centrifugal, positive displacement, agricultural, residential, specialty, and solar pumps, serve specific purposes in different sectors.

How does a water pump work?

Water pump function is based on creating a low-pressure environment, using impellers (centrifugal pumps) or mechanical contraction (positive displacement pumps) to move water efficiently.

What factors should I consider when selecting a water pump?

When selecting a water pump, consider the required flow rate, power source (AC, DC, gasoline, diesel, solar), and the specific application (residential, agricultural, specialty) to ensure optimal performance.

How can I maintain my water pump?

To maintain a water pump, regularly check and lubricate moving parts, inspect and replace seals, monitor and maintain the power source, and keep the pump clean from debris, following manufacturer guidelines for proper maintenance.