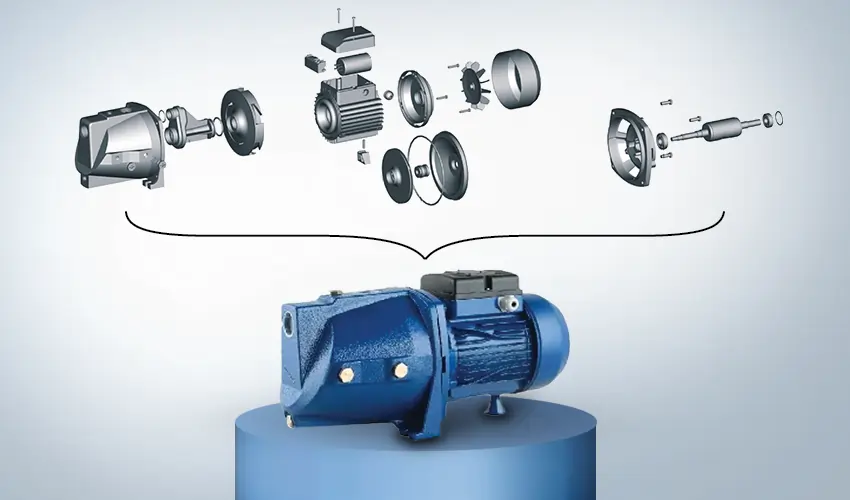

Jet Pump Components

Jet pump components are integral to the operation of a jet pump system. These components work together to create suction, generate pressure, and deliver water for various applications.

The Importance of Jet Pump Components

Jet pump components are crucial for its effective operation and performance. Each component serves a specific purpose and contributes to the overall functionality of the system. Understanding the importance of these components is vital for proper installation, maintenance, and troubleshooting of jet pumps. Here are some key reasons why jet pump components are important:

1. Impeller: The impeller is responsible for generating the centrifugal force that propels water through the pump. It plays a critical role in creating water flow and pressure.

2. Diffuser: The diffuser helps convert the kinetic energy of the water into pressure energy. It increases the pressure of the water, ensuring efficient water delivery.

3. Nozzle/Jet Assembly: The nozzle or jet assembly creates the pressure differential that draws water into the pump. It determines the pump’s suction capability and influences its overall efficiency.

4. Suction Line: The suction line connects the pump to the water source and allows water to be drawn into the pump. It must be properly sized, sealed, and free from leaks to ensure optimal suction and prevent airlocks.

5. Discharge Pipe: The discharge pipe transports pressurized water from the pump to the desired outlet or storage location. It must be appropriately sized and installed to maintain efficient water flow.

6. Motor: The motor provides the power necessary to drive the pump. It is essential to match the motor’s capacity to the pump’s requirements for reliable and efficient operation.

7. Pressure Switch: The pressure switch is commonly used in jet pump systems for water supply. It automatically controls the pump’s operation based on the desired pressure settings, ensuring consistent water pressure.

What Components are used in a Jet Pump?

Jet pumps typically consist of the following components: 1. Motor: The motor provides the power to drive the pump. It can be an electric motor or an internal combustion engine, depending on the type of jet pump.

2. Impeller: The impeller is a rotating component that creates centrifugal force, accelerating the water inside the pump. It is responsible for generating the initial suction and water flow.

3. Diffuser: The diffuser is a stationary component that receives the high-velocity water from the impeller. It helps convert the kinetic energy of the water into pressure energy, increasing the water pressure before it is discharged.

4. Nozzle/Jet Assembly: The nozzle or jet assembly is a critical component in a jet pump. It consists of a venturi-shaped nozzle or jet that creates a pressure differential, which draws water from the water source into the pump.

5. Suction Line: The suction line connects the jet pump to the water source, such as a well or a tank. It allows water to be drawn into the pump’s intake. The suction line may include pipes, fittings, and valves.

6. Discharge Pipe: The discharge pipe carries the pressurized water from the pump to the desired outlet or storage tank. It is typically connected to the jet assembly or the diffuser outlet.

7. Pressure Switch: In some jet pump systems used for water supply, a pressure switch is included. It senses the pressure in the system and automatically turns the pump on or off to maintain the desired pressure range. What happens if a component fails If a component in a jet pump fails, it can have various consequences depending on the specific component and its function within the system.

Here are some potential outcomes of component failures:

1. Impeller Failure: A failed or damaged impeller may result in reduced water flow or complete loss of pumping capacity. This can lead to decreased performance, inadequate water supply, or even pump motor overload.

2. Motor Failure: If the motor fails, the pump will not receive the necessary power to operate. This can result in a complete loss of pumping capability and require motor repair or replacement.

3. Nozzle/Jet Assembly Failure: A malfunctioning nozzle or jet assembly can disrupt the pressure differential necessary for water intake. This may lead to a loss of suction, reduced pump efficiency, and insufficient water flow.

4. Suction Line Failure: Leaks, cracks, or blockages in the suction line can introduce air or hinder water intake. This can cause airlocks, reduced pumping capacity, or complete pump failure.

5. Discharge Pipe Failure: A damaged or improperly sized discharge pipe can restrict water flow and increase backpressure on the pump. This can result in decreased performance, loss of water pressure, or even damage to the pump.

6. Pressure Switch Failure: If the pressure switch fails, it may not accurately sense the pressure in the system or trigger the pump as needed. This can lead to irregular water supply, inconsistent pressure, or excessive cycling of the pump.

Conclusion

Parts of jet pump are essential for its proper operation and performance. Each component has a specific function that contributes to the overall functionality of the pump system. From the impeller and diffuser to the suction line and discharge pipe, every component plays a crucial role in generating suction, creating pressure, and delivering water. If any component fails, it can lead to reduced performance, inadequate water flow, or even complete pump failure. Regular inspection, maintenance, and prompt repair or replacement of faulty components are necessary to ensure the reliable and efficient operation of a jet pump system.