What Is a Generator Alternator?

A generator alternator, often referred to simply as an alternator, is a device used in electrical engineering to generate alternating current (AC). It works on the principle of electromagnetic induction, where a rotating magnetic field induces an alternating current in a conductor.

In an alternator, a rotor (the rotating part) is turned within a stationary set of conductors to produce electrical power. Typically, the rotor contains a set of magnets or electromagnets, and the stator (the stationary part) consists of wire coils arranged to capture the changing magnetic field and convert it into electrical energy.

Alternators are commonly used in vehicles to charge the battery and power the electrical systems while the engine is running. They are also used in power plants, wind turbines, and various other applications where AC power generation is required. Alternators are preferred over traditional generators in many applications due to their higher efficiency, lighter weight, and lower maintenance requirements.

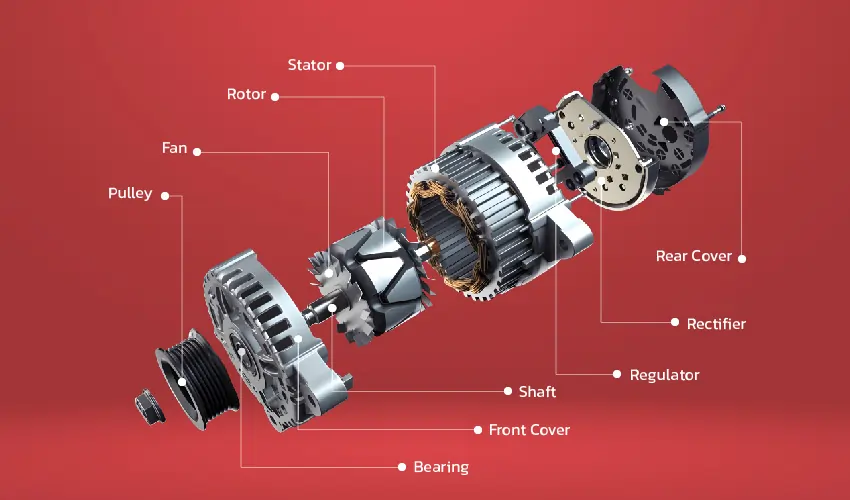

Key Generator Alternator Parts

The key parts of generator alternator include:

- Rotor: The rotating part of the alternator that generates the magnetic field. It can be made up of permanent magnets or electromagnets.

- Stator: The stationary part of the alternator consisting of wire coils wound around an iron core. When the rotor rotates, it induces an alternating current in the stator windings.

- Exciter: In larger alternators, an exciter is used to provide the initial magnetic field to the rotor. This excitation can be provided by a separate DC power source or by a portion of the alternator’s output.

- Rectifier: In automotive alternators and many other applications, a rectifier is used to convert the alternating current generated by the stator into direct current (DC) for charging the battery or powering DC loads.

- Voltage Regulator: This component regulates the output voltage of the alternator to ensure that it remains within the desired range, typically around 13.8 to 14.5 volts in automotive applications.

- Bearings: Bearings support the rotor shaft, allowing it to rotate smoothly within the stator. Good quality bearings are crucial for minimizing friction and ensuring the longevity of the alternator.

- Cooling System: Alternators often have a cooling system, such as a fan or air vents, to dissipate heat generated during operation. Overheating can degrade the performance and lifespan of the alternator.

- Housing/Enclosure: The housing or enclosure of the alternator protects its internal components from environmental factors and provides structural support.

Rotor

The rotor is a crucial component of a generator alternator, responsible for generating the magnetic field necessary for inducing an electrical current in the stator windings. It’s typically the rotating part of the alternator assembly and plays a fundamental role in the conversion of mechanical energy into electrical energy through the process of electromagnetic induction.

Types of rotor including:

- Electromagnetic Rotor: In this type, the rotor produces a magnetic field when current flows through the rotor windings. This type allows for control over the strength of the magnetic field and, consequently, the output of the alternator.

- Permanent Magnet Rotor: Permanent magnet rotors utilize permanent magnets that maintain their magnetic properties without requiring an external power source. This design simplifies the construction and eliminates the need for a separate excitation system, leading to higher efficiency and reliability in certain applications.

Stator

The stator is a stationary component of a generator alternator and is integral to the process of converting mechanical energy into electrical energy through the principle of electromagnetic induction. It works in conjunction with the rotor to generate alternating current (AC) by capturing the changing magnetic field produced by the rotor’s rotation.

Diodes

A diode is a two-terminal electronic component with asymmetric conductance. It allows current to flow in one direction with low resistance (forward biased) and blocks current flow in the opposite direction with high resistance (reverse biased). Diodes are fundamental building blocks in electronic circuits and serve various purposes, including rectification, signal demodulation, voltage regulation, and switching.

Diodes have numerous applications in electronics, including:

- Rectification: Converting alternating current (AC) to direct current (DC) in power supplies.

- Signal Demodulation: Extracting modulated signals from carrier waves in radio and communication systems.

- Voltage Regulation: Stabilizing voltage levels in power supplies and voltage reference circuits.

- Switching: Controlling the flow of current in electronic switches and relays.

Voltage Regulator

A voltage regulator is an electronic circuit or device designed to maintain a constant voltage level despite changes in input voltage, load current, or temperature. Its primary function is to stabilize the output voltage within a specified range, ensuring that electronic devices receive a reliable and consistent power supply.

Types of Voltage Regulator

- Linear Voltage Regulators: These regulators use a series pass transistor to control the output voltage. They are simple in design and provide low output ripple and noise but are less efficient, especially when the input-output voltage differential is high.

- Switching Voltage Regulators: Also known as DC-DC converters, switching regulators use high-frequency switching techniques to regulate the output voltage. They offer higher efficiency and are suitable for applications where input-output voltage differentials are significant. Common types include buck, boost, and buck-boost regulators.

- Zener Diode Voltage Regulators: Zener diodes can also be used to regulate voltage by maintaining a constant voltage drop across the diode. However, they are less efficient and suitable only for low-power applications.

- Integrated Voltage Regulator Chips: These are complete voltage regulator circuits integrated into a single IC (integrated circuit) package. They provide a compact and convenient solution for voltage regulation in various electronic devices.

Bearings

Bearings are mechanical components used to reduce friction between moving parts and support rotational or linear motion within a machine or system. They facilitate smooth movement by allowing one part to glide over another with minimal resistance, thereby enabling efficient operation and prolonging the lifespan of the machinery. Bearings are found in various applications, ranging from simple household appliances to complex industrial machinery.

Types

- Ball Bearings: Ball bearings consist of rolling elements (balls) placed between inner and outer raceways. They are designed to support radial and axial loads and are commonly used in applications with moderate to high-speed rotation, such as automotive wheels, electric motors, and industrial machinery.

- Roller Bearings: Roller bearings utilize cylindrical or tapered rollers instead of balls to support loads. They offer higher load-carrying capacity than ball bearings and are suitable for applications with heavy radial or axial loads, such as conveyor systems, machine tools, and automotive transmissions.

- Plain Bearings: Also known as bushings or sleeve bearings, plain bearings consist of a shaft rotating within a stationary sleeve. They rely on a thin layer of lubricant (e.g., oil or grease) to reduce friction and support the load. Plain bearings are commonly used in low-speed or oscillating motion applications, such as hinges, pivots, and sliding mechanisms.

- Thrust Bearings: Thrust bearings are designed to support axial loads, either uni-directional or bi-directional, along the axis of rotation. They can be constructed using ball bearings, roller bearings, or plain bearings and are commonly found in applications such as automotive transmissions, propeller shafts, and thrust reversers in jet engines.

Brushes and Slip Rings

Brushes and slip rings are components commonly used in electrical machines, such as motors, generators, and certain types of alternators. They play a crucial role in transferring electrical power and signals between stationary and rotating parts of the machine.

Brushes

- Function: Brushes are conductive components typically made of carbon or graphite that make physical contact with rotating elements, such as the commutator or slip rings, to transfer electrical current between stationary and rotating parts.

- Application: Brushes are commonly used in DC motors, where they facilitate the commutation process by maintaining electrical contact with the commutator segments as the rotor rotates.

- Construction: Brushes are typically held in brush holders mounted on the stationary part of the machine. They exert pressure against the rotating element to ensure good electrical contact while allowing for wear compensation.

- Materials: Brushes are often made from carbon or graphite due to their low friction, good electrical conductivity, and resistance to wear. Other materials, such as metal-graphite composites, may also be used for specific applications.

Slip Rings

- Function: Slip rings are conductive rings or cylindrical components mounted on the rotating shaft of an electrical machine. They provide a continuous electrical connection between stationary and rotating parts, allowing for the transfer of power, signals, or data.

- Application: Slip rings are commonly used in AC generators, wind turbines, and certain types of alternators, where they enable the transmission of electrical power from the rotating rotor to the stationary load.

- Construction: Slip rings consist of a conductive ring or rings mounted on an insulating shaft. Brushes, positioned against the slip rings, make electrical contact with them to establish the connection.

- Materials: Slip rings are typically made from materials with good electrical conductivity, such as copper or brass, to minimize electrical resistance and losses.

Pulley and Belt

Pulleys and belts are mechanical components commonly used to transmit power between rotating shafts in machinery and equipment. They form a simple and efficient means of transferring motion and power from one location to another, allowing for the operation of various devices in industries ranging from manufacturing to transportation.

Here’s a description of pulleys and belts:

Pulleys

- Function: A pulley is a rotating wheel with a grooved rim designed to guide and support a flexible belt or rope. It serves to change the direction of a force or transmit rotational motion between two or more shafts.

Belts

- Function: Belts are flexible loops made of materials such as rubber, polyurethane, or synthetic fibers, designed to transmit power between pulleys by wrapping around them. They provide a non-slip, friction-based mechanism for transferring rotational motion.

Conclusion

Generator alternator spare parts, including the rotor, stator, rectifier, voltage regulator, bearings, cooling system, and housing, work together to efficiently generate and regulate alternating current (AC) electricity. These components play critical roles in converting mechanical energy into electrical energy, ensuring stable power output, and maintaining the reliability and longevity of the alternator across various applications.