Diesel generator sets are vital for providing backup or primary power in various applications. Efficient diesel generator set troubleshooting is crucial to swiftly identify and address issues, ensuring the continued reliability of the generator set.

How does Diesel Generator Set Work?

A diesel generator set, also known as a genset, is a device that converts diesel fuel into electrical energy. It is commonly used as a backup power source or as the primary source of electricity in areas where a stable power supply from the grid is not available. Here’s a basic overview of how a diesel generator set works:

A diesel generator set, also known as a genset, is a device that converts diesel fuel into electrical energy. It is commonly used as a backup power source or as the primary source of electricity in areas where a stable power supply from the grid is not available. Here’s a basic overview of how a diesel generator set works:

Diesel Engine

The heart of a diesel generator set is the diesel engine. This internal combustion engine operates on the principle of diesel cycle, where air is compressed and then fuel is injected into the compressed air, leading to combustion.

Air Intake and Compression

The process starts with the air intake. Air is drawn into the engine through an air filter to remove impurities. The air is then compressed in the cylinders of the engine by a piston. The compression raises the temperature of the air.

Fuel Injection

Diesel fuel is injected into the highly compressed air at the end of the compression stroke. The high temperature of the compressed air causes the diesel fuel to ignite spontaneously.

Combustion

The injected diesel fuel combusts, producing a high-pressure, high-temperature mixture of gases. This combustion process drives the piston down the cylinder.

Power Generation

The movement of the piston is connected to a crankshaft, which converts the linear motion of the piston into rotary motion. The rotary motion is used to turn the generator’s rotor, which is surrounded by a stationary coil of wire. This relative motion induces an electromotive force (EMF) in the coil, generating electrical energy.

Voltage Regulation

The generator includes a voltage regulator to maintain a stable output voltage. This is crucial for ensuring that the electrical devices connected to the generator receive a consistent and reliable power supply.

Cooling System

Diesel generators generate a significant amount of heat during operation. Therefore, they are equipped with a cooling system (usually involving a radiator and a cooling fan) to dissipate excess heat and prevent the engine from overheating.

Exhaust System

The exhaust gases produced during combustion are expelled through an exhaust system. This system often includes a muffler to reduce noise.

Control Panel

The generator set is equipped with a control panel that allows the user to start and stop the generator, monitor its performance, and sometimes configure various settings.

Fuel System

A fuel system, including a fuel tank, fuel pump, and fuel injectors, is responsible for delivering the required amount of diesel fuel to the engine.

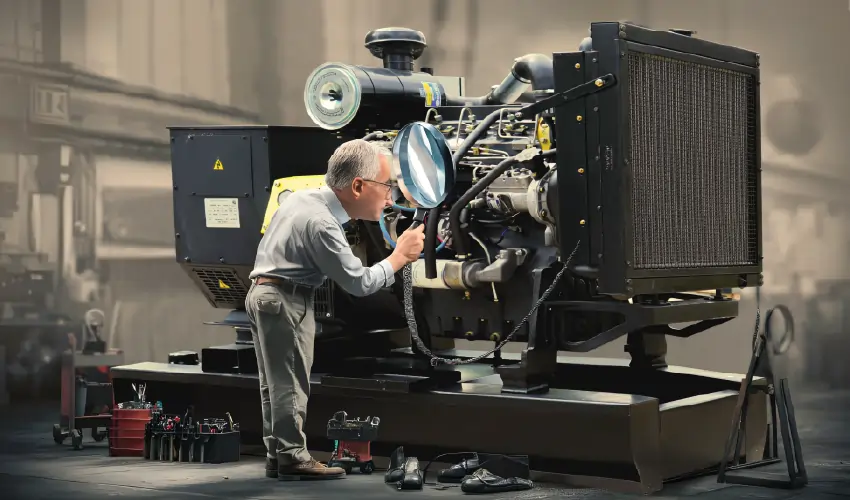

What is Diesel Generator Set Troubleshooting?

Diesel generator set troubleshooting involves identifying and resolving issues that may arise during its operation. Here are common troubleshooting steps for diesel generator sets:

Check Fuel Supply

Ensure there is an adequate supply of diesel fuel in the fuel tank. Verify that the fuel lines are not clogged, and the fuel filters are clean.

Inspect Air Intake and Filters

Check the air intake system for any obstructions or blockages. Clean or replace air filters to ensure proper air flow.

Battery Inspection

Ensure the batteries are charged and in good condition. Check battery terminals for corrosion and secure connections.

Examine Cooling System

Inspect the cooling system for leaks or low coolant levels. Clean the radiator and ensure the cooling fan is functioning properly.

Review Oil Levels and Quality

Check the oil level in the engine. Top up if necessary. Ensure the oil is of the correct type and in good condition.

Inspect Exhaust System

Check for any blockages or restrictions in the exhaust system. Ensure the exhaust pipe and muffler are in good condition.

Verify Control Panel Settings

Review the control panel settings for proper configuration. Check for any error codes or alarms displayed on the control panel.

Fuel Injector Inspection

Inspect fuel injectors for cleanliness and proper functioning. Clean or replace injectors as needed.

Inspect Belts and Pulleys

Check the condition of drive belts and pulleys. Ensure proper tension and replace worn-out components.

Check for Leaks

Inspect the engine and generator set for any fluid leaks. Address any leaks promptly to prevent damage and maintain proper operation.

Verify Voltage Output

Use a multimeter to check the voltage output of the generator. Ensure the voltage is within the specified range.

Examine Wiring and Connections

Inspect electrical wiring for damage or loose connections. Tighten connections and replace damaged wiring.

Governor Adjustment

If the engine speed is not consistent, check the governor settings and adjust if necessary.

Refer to the User Manual

Consult the user manual for the specific generator model for troubleshooting guidance and recommended maintenance procedures.

How to Choose the Right Diesel Generator Set?

Choosing the right diesel generator set involves considering various factors to ensure it meets your specific power requirements and operational needs. Here are key considerations to help you make an informed decision:

Power Requirements: Determine the total power (kW or kVA) your facility or equipment requires during normal operation and peak loads. Choose a generator with a capacity that comfortably meets these requirements.

Load Type: Consider the type of load the generator will be supporting (e.g., resistive, inductive, or capacitive). Different loads may require specific generator characteristics.

Voltage and Phase Requirements: Ensure the generator’s output voltage and phase match the requirements of the equipment it will be powering. Common voltages include 120V, 240V, 480V, and generators can be single-phase or three-phase.

Fuel Efficiency: Look for a generator set that offers good fuel efficiency. This is important for minimizing operating costs over time, especially if the generator will be used frequently.

Fuel Type: Diesel generators are common, but there are also generators that run on other fuels like natural gas or propane. Choose the fuel type that is readily available and cost-effective in your location.

Run Time and Tank Size: Consider the generator’s run time on a full tank. Generators with larger fuel tanks may provide longer run times, which can be crucial for extended power outages.

Emissions Compliance: Check if the generator complies with local emissions regulations. Some areas have strict emissions standards that generators must adhere to.

Noise Level: If the generator will be used in a residential or noise-sensitive area, consider its noise level. Some generators come with soundproof enclosures or are designed to operate quietly.

Installation and Location: Assess the space available for installation and ensure the generator set fits within the designated area. Consider the environmental conditions, such as temperature and humidity, at the installation site.

Automatic Transfer Switch (ATS): An ATS enables automatic switching between the main power supply and the generator during a power outage. Ensure the generator is compatible with the ATS for seamless operation.

Ease of Maintenance: Choose a generator set with accessible components for routine maintenance tasks. Regular maintenance is crucial for the longevity and reliability of the generator.

Brand and Warranty: Select a reputable manufacturer with a history of producing reliable generators. Check the warranty offered, as it reflects the manufacturer’s confidence in their product.

Budget: Consider your budget constraints. While it’s important not to compromise on quality, finding a generator that meets your requirements without unnecessary features can help control costs.

Consultation with Experts: If needed, seek advice from generator experts, engineers, or consultants to ensure you make the right choice based on your specific requirements.

What are Diesel Generator Set Preventative Maintenance Tips?

Preventive maintenance is crucial to ensure the reliable and efficient operation of a diesel generator set. Regular maintenance helps identify potential issues before they become serious problems. Here are some preventive maintenance tips for diesel generator sets:

Read the User Manual: Familiarize yourself with the manufacturer’s recommendations and guidelines provided in the user manual. It contains valuable information on maintenance schedules, procedures, and specifications.

Regular Inspection: Conduct regular visual inspections of the generator set. Check for any signs of leaks, loose connections, or abnormal wear and tear.

Fuel System Maintenance: Monitor the fuel system for contaminants. Drain the water separator regularly to remove any accumulated water or impurities. Clean or replace fuel filters at the recommended intervals.

Oil Changes: Change the engine oil and oil filter according to the manufacturer’s recommendations. Regular oil changes help maintain engine performance and extend the life of the generator.

Cooling System Maintenance: Check coolant levels regularly and top up if necessary. Ensure the coolant mixture is correct for the ambient temperature. Clean the radiator and cooling fan to prevent overheating.

Battery Maintenance: Inspect the batteries for corrosion and ensure the terminals are clean and securely connected. Test the batteries regularly and replace them as needed.

Exhaust System Inspection: Inspect the exhaust system for any leaks, damage, or corrosion. Check the exhaust pipe, muffler, and other components for proper functioning. Air Intake System: Keep the air intake system clean and free from obstructions. Replace air filters as recommended to ensure optimal airflow.

Check Belts and Pulleys: Inspect drive belts for wear and proper tension. Replace worn-out belts and check pulleys for alignment. Inspect Wiring and Connections: Regularly check electrical wiring for damage or signs of wear. Tighten loose connections and replace damaged wiring promptly.

Governor Adjustment: Ensure the governor is properly adjusted to maintain the desired engine speed.

Load Bank Testing: Conduct load bank testing periodically to simulate the generator’s full load capacity. This helps prevent wet stacking and ensures the generator operates efficiently.

Automatic Transfer Switch (ATS): If the generator is connected to an automatic transfer switch, test its functionality regularly to ensure seamless transitions during power outages.

Record Keeping: Maintain a detailed maintenance log that includes all maintenance activities, inspections, and repairs. This information is valuable for tracking the generator’s performance over time.

Professional Inspection: Schedule regular inspections by a qualified technician. Professional inspections can identify potential issues that may not be apparent during routine checks.

Conclusion

In conclusion, diesel generator set common problem involves systematically addressing issues related to fuel, air intake, batteries, cooling, exhaust, and electrical components. Regular maintenance, prompt identification of problems, and adherence to manufacturer guidelines are essential to ensure the reliable operation of the generator set and prevent unexpected failures.